Chapter 11

DISTILLATION

DISTILLATION THEORY

The object of distillation is the separation of the alcohol from the other ingredients in the beer, mostly water. In making fuel alcohol it is necessary to get all of the alcohol and water separated if the alcohol is going to be mixed with gasoline, and most of the alcohol and water separated if the alcohol is going to be burned in a converted engine. As will be seen, the purer the alcohol, the harder it is to make.

The separation of the alcohol and water by distillation is made possible by the fact that alcohol boils at about 173 degrees F. and water at 212 degrees F. When the mixture of water and alcohol is boiled, vapors with a greater concentration of alcohol will be formed and liquid with a lesser concentration of alcohol will remain behind. However, because water and alcohol do not form what is called an "ideal" mixture, the separation cannot be done in one clean step.

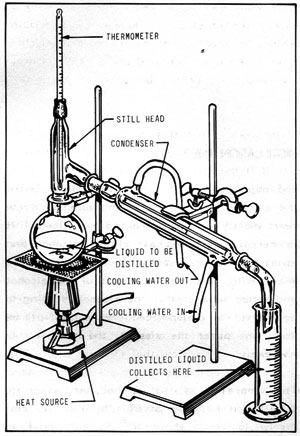

Figure 11 -1: SIMPLE DISTILLATION APPARATUS

Figure 11-1 illustrates a simple distillation apparatus using laboratory-type equipment. Note that the equipment consists basically of a container for the liquid to be distilled (still pot), a heat source, and a condenser to turn the distilled vapors back into liquid form. The thermometer is necessary to monitor the temperature of the vapors.

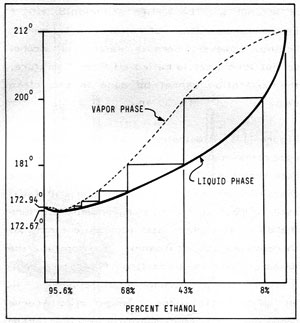

Figure 11-2: BOILING POINT COMPOSITION for LIQUID and VAPOR PHASES

In Figure 11-2, the heavy solid curve represents the composition of the liquid phase of water/ethanol mixtures plotted against the temperature at which the mixture boils. The dotted curve represents the vapor phase. Using the apparatus illustrated, and starting with a concentration of 8% alcohol in water, the liquid will boil at about 200 degrees F. Reading across, the vapors will contain about 43% alcohol. Clearly, for fuel purposes, a purer product is needed. To this end, we must redistill the condensed vapors from the first distillation which contain 43% alcohol and 57% water. This mixture will boil at about 181 degrees F. and the vapors will contain about 68% alcohol. Each time the condensed vapors are redistilled, they will be slightly purer, but many separate distillations are needed to produce relatively pure alcohol. Fortunately, a type of distillation apparatus, called a reflux (or rectifying column), in effect, performs simultaneous distillations and will be described later.

However, with the equipment described, no matter how elaborate, the purest alcohol that can be produced is 95.6%. The remaining 4.4% water is impossible to remove because at this ratio, water and alcohol form a constant boiling mixture (called an "azetrope") whose boiling point is a fraction of a degree below that of pure alcohol , and separation by ordinary distillation is impossible. Special techniques that can remove this residual water are outlined later in Chapter 12.

THE REFLUX COLUMN

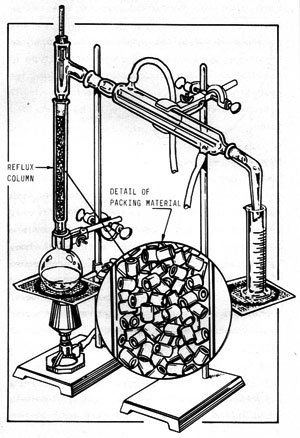

Figure 11-3 illustrates a reflux column installed on the simple apparatus described in Figure 11-1. In this laboratory version, the reflux column consists merely of a glass tube filled with packing material. In this case, the packing is short lengths of small-diameter glass tubing. The purpose of the packing is to provide as large an internal surface area as possible.

Figure 11-3: REFLUX DISTILLING APPARATUS

As the vapors from the still pot ascend through the column, they condense on the packing material and drip downward. Additional ascending vapors contact the descending liquid (called "reflux") and revaporize it. Thus, as the vapors slowly work their way up the column, they become richer and richer in alcohol until, when they reach the top, they are relatively pure. Meanwhile, the descending liquid is stripped of its alcohol. The overall effect is that many "distillations" are performed simultaneously and the liquid in the still pot is stripped of its alcohol in one continuous operation.

Reflux columns can be constructed to operate on either a batch or continuous basis and are described in Chapter 14.

Chapter Index

Chapter 1 AN OVERVIEW

Chapter 2 BASIC FUEL THEORY

Chapter 3 UTILIZATION OF ALCOHOL FUELS

Chapter 4 ETHANOL PRODUCTION - GENERAL DISCUSSION

Chapter 5 PROCESSING STEPS COMMON TO ALL MATERIALS

Chapter 6 PROCESSING STEPS SPECIFIC TO SACCHARINE MATERIALS

Chapter 7 PROCESSING STEPS SPECIFIC TO STARCHY MATERIALS

Chapter 8 PROCESSING STEPS SPECIFIC TO CELLULOSE MATERIALS

Chapter 9 YEAST AND FERMENTATION

Chapter 10 INDIVIDUAL RAW MATERIALS

Chapter 11 DISTILLATION

Chapter 12 DRYING THE ALCOHOL

Chapter 13 MASHING AND FERMENTATION EQUIPMENT

Chapter 14 DISTILLATION EQUIPMENT

Chapter 15 SOLAR STILLS

Chapter 17 PUTTING IT ALL TOGETHER

Chapter 18 THE FUTURE

Biofuels

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?