Now that the "grassroots" homemade alcohol fuel movement is rapidly gaining momentum, it's no wonder that farmsteaders and town dwellers alike are searching for simple, cost-effective ways to "brew up their own". And, of course, the major start-up expense -- especially for a smallscale operation -- is the cost of the equipment itself.

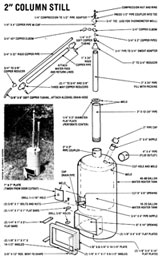

With this concern in mind, MOTHER is glad to provide her readers with a couple of backyard still designs from alcohol researcher/self-publisher Clarence Goosen, which have not only proven themselves effective, but which anyone with welding skills can construct inexpensively in a matter of hours.

Click here for larger image

The first distillery -- simply a tank within a tank -- makes a great "test bed" for various column designs and mash recipes. By scrounging parts, anyone should be able to construct the mini-still for about $25, and the tiny "percolator" can turn out almost 1/2 gallon of 180-proof fuel per hour.

The major components of Clarence's baby distillery are two discarded water heater tanks (formerly electrically fired models are easier to work with, and nongalvanized units don't give off noxious fumes during the cutting and welding process as do their "coated" cousins), some pipe for the column, filler, and drain, copper conduit for the condenser assembly, and a few assorted fittings and pieces of steel stock.

When choosing the tanks you'll use, make sure your "vat-to-be" is leak-free, and about 4" smaller in diameter (and 12" to 16" shorter in height) than is the "firebox" container. Before you cut the top off the larger tank and weld the small cauldron to it, mark the spot where the drain pipe will protrude through the firebox wall, and cut a 6" x 6" opening in the larger container's jacket at that point.

Follow our exploded drawing to assemble the remainder of your "budget" still. The two-inch column can be filled with rolled-up nylon window screening, or -- if you weld a perforated plate at the bottom of the tube -- it can be packed with short sections of 1/2" copper conduit, loosely woven rustproof metal scrubbing pads, or commercial packing (if you're willing to pay the additional cost of the manufactured material).

The condenser is nothing more than a conduit set within a larger tube that serves as a water jacket. (If you want to keep track of column temperature for testing purposes, replace the outlet elbow for the vapors with a tee fitting, which can then be adapted to serve as a thermometer well.)

A Slightly Larger Unit, Too

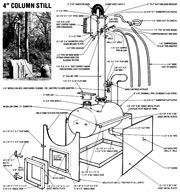

The second design -- a four-inch column model -- is capable of producing about two gallons per hour of 90% pure ethanol fuel. Naturally, because this model is larger and somewhat more sophisticated than the two-inch column still, its cost is greater, but the entire assembly can probably be built for under $200 in about 30 hours of spare time tinkering in your shop.

Although the illustration is largely self-explanatory, there are a few fine points that should be mentioned. The 40- to 80-gallon tank should, of course, be leak-free and preferably nongalvanized, and all its unused fittings must be plugged. Since the column will have to be filled with pall rings (or some other loose material), it will also be necessary to insert a drilled packing support plate in the pipe -- at its bottom flange -- to prevent the packing from falling into the mash vat.

Click here for larger image

Both the internal heat exchanger and the condenser are simply lengths of 1/4" O.D. copper tubing, wound into 2"-diameter coils and held in place -- within their respective columns -- by compression-to-pipe adapters, which are themselves fastened to pipe couplers welded to the tube's walls. (The coils can be formed by wrapping the soft tube around a 1-1/2" thick section of pipe or wooden dowel.) Since the amount of water flow controls the critical temperature within the packed tower, the rush of cooling liquid -- to the column, at least -- should be regulated by a needle valve on the supply side, although separate controls and lines to the heat exchanger and condenser (using a tee and a single water-return hose) may be more practical. Remember, too, that you may want to install a thermometer well at the top of the column, in order to keep vapor temperatures within the desirable 175-180 deg F (79.4-82.2 deg C) range.

Though neither of these two stills will -- by itself -- be capable of producing all the fuel an average American family consumes, either one certainly would be able to supply a motorcycle, home-generating unit, garden tractor, or any of countless other normally gasoline-powered pieces of equipment that are in use on homesteads and in communities across the country today ... and that's certainly nothing to sneeze at, especially when there may eventually be no gasoline available in this nation for long periods of time!

EDITOR'S NOTE

Complete step-by-step, illustrated plans for both stills shown here, plus drawings for a larger-capacity 8"-column distillery -- as well as detailed explanations of the operation, design, and characteristics of packed column stills -- are included in Goosen's EtOH Fuel Book, an eight-volume continuing publication available for $40 (1 year, 4 issues) or $60 (2 years, 8 issues) post-paid from The Harvester Press, Dept. TMEN, P.O. Box 1669, Hendersonville, North Carolina 28793. Single copies of the first issue only (which details the four-inch column still design) can be ordered -- for $11 post-paid -- from the same address.

Also, MOTHER has fully illustrated, step-by-step plans available for her own 3" and 6" column stills, at $15 each post-paid, and she's offering an alcohol fuel kit (which includes your choice of either of the still plans, plus enzymes, a hydrometer, a fermentation lock, complete instructions on how to use each item, and a copy of Brown's Alcohol Motor Fuel Cookbook [see below]) for a price of $45 post-paid. Send your orders for any of these items to Mother's Plans, P.O. Box A, East Flat Rock, North Carolina 28726.

Finally, we'd like to remind everyone, once again, that a permit -- from the U.S. Bureau of Alcohol, Tobacco, and Firearms -- is absolutely necessary for anyone experimenting with producing ethanol fuel. Don't distill alcohol without one -- you'll be breaking the law and could harm the entire alternative liquid fuel movement by doing so!

BATF Alcohol Programs -- FAQs, Information, Permits, Regulations:

http://www.atf.treas.gov/alcohol/index.htm

Alcohol Motor Fuel Cookbook, by Mike Brown -- How to ferment grain into alcohol and modify carburetors to run on it. One of the originals, new edition now available. US$20.

http://home.earthlink.net/~dlaw70/alteng.htm#bamfc

Alcohol Distiller's Handbook, by Mike Brown -- covers milling, mashing, fermentation, distillation, distillers' dried grain and solubles and laboratory control. Perfect for personal fuel self-sufficiency or commercial production. $25

http://home.earthlink.net/~dlaw70/alteng.htm

How To Build A Junkyard Still, by Mike Brown -- be your own motor fuel magnate. $12.00.

http://home.earthlink.net/~dlaw70/alteng.htm#junkyard

Mother Earth Alcohol Fuel

Chapter 1

Introduction to a Farmer's Fuel ... Alcohol

Introductory Overview of the Alcohol Production Flow Chart

A Short But Complex Story About Enzymes and Their Functions

Chapter 2

Farm Crops for Alcohol Fuel

Raw Materials

More on Raw Materials

Feedstock Handling and Storage

Chapter 3

Basic Steps in the Production of Ethyl Alcohol

More On Conversion and Fermentation

Fermentation Addendum

Alcohol Yield

Chapter 4

Control of Infection by Planned Sanitation in the Production of Fuel or Gasohol Alcohol

Chapter 5

MOTHER's Mash Recipes for Alcohol Production

Important! Read Before Making Mash

Preparing a Mash From Saccharide-rich Materials

A Handy Hydrometer Jacket

Chapter 6

Distiller's Feeds

By-product Utilization

Animal Feed By-product

More Information On By-product Utilization

Chapter 7

How the Distillation Process Works

Packed Column

Perforated Plate

Bubble Cap Plate

Solar Stills

The Reasoning Behind MOTHER's Still Design

Still Operation

Making Your First "Run"

"Economizing" Your Alcohol Production

Chapter 8

Six-Inch Column Still Plans

Three-Inch Column Still Plans

Bill of Materials

Chapter 9

Two Low-cost Backyard Stills

How To Adapt Your Automobile Engine For Ethyl Alcohol Use

Ron Novak's Do-It-Yourself Water Injection System

Biofuels

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?

Mother’s Alcohol Fuel Seminar

Mother’s Alcohol Fuel Seminar