Appendix A

The Indore Process and its Evolution

As was explained in the text of this book composting is no new idea; in addition to what is done by the Chinese many primitive peoples make some sort of compost to put on their land; their methods and success vary. The old gardeners' practice in Europe of saving the leaf-fall and making it up into heaps is something of the kind; it is very slow, for the heap takes two years to mature, it lacks the lignified cellulose supplied by the twigs and branches and above all it lacks the animal element. True composting can be said to be achieved only when the vegetable and animal elements are combined in correct proportions and have been subjected to the influence of moisture and of air.

The Indore Process, of which a general description was given in Chapter 7, owes its origin to the conviction which gradually impressed itself on the mind of its inventor, Sir Albert Howard, during the years of his career as an officer in the Department of Agriculture of the Imperial Government of India, that there was little point in offering to the Indian cultivator improved varieties of the crops to be grown unless one initial difficulty could be solved. Owing to the habit of burning three-fourths of the cow-dung it was impossible to fertilize the fields up to the point where they could grow the improved varieties with any success; on the contrary, it was more than likely that such improved varieties would only tend unduly to exhaust the soil. In looking for the solution of this problem it seemed obvious to try out methods which had been known in China for over four thousand years. The investigations into the making and efforts of compost, the temperature, chemical, and biological tests were carried on from time to time for many years by Sir Albert Howard himself and by his wife and personal assistant, Gabrielle Howard; they were finally completed at Indore, where Mr. Yeshwant Wad cooperated in the chemical work. The result was the Indore Process, so named in acknowledgement of the generosity of the Maharajah Holkar and the Durbar of the State of Indore, who provided the site for the Institute where the final stages of the work were carried out. It is not too much to say that the Indore Process is the result of twenty-six years' scientific investigation implying an expenditure of £100,000 at three different Experiment Stations, Pusa, Quetta, and Indore.

The book describing this work, which was published in 1931 under the title The Waste Products of Agriculture: their Utilization as Humus, was addressed principally to the Indian public. It did not occur to the inventor of the Process that the principles worked out by him would have a world-wide application. The facts about the deterioration of soils were not at that time so well known; the phenomenon known as the dust bowl did not appear in North America in any marked degree until 1932 or 1933 and only became disastrous in 1934 and 1935. It was in the course of a holiday voyage round Africa in 1932-3 that a visit to one of Colonel Grogan's estates in Kenya Colony first suggested a wider field of work. Further contacts with others interested confirmed a decision to abandon all competing interests and to apply the leisure of retirement to a campaign for encouraging the Process.

This almost at once began to widen out and to embrace far more profound problems. The whole meaning and basis of soil fertility seemed to call for reflection and comment; ideas were rapidly evolved which threw a flood of light both on previous work and on the many current experiences which were being communicated from all parts of the world. Eventually contact with the Local Medical and Panel Committee of the County Palatine of Cheshire, which, under the leadership of Drs. Kerr and Picton, did such notable pioneering work in the stand taken in the well-known Medical Testament, confirmed in the field of human health ideas which had been tested out in the Indian days on many kinds of crops and to some extent on animals. The generous interest of the late Sir Bernard Greenwell provided a welcome addition of facts in the latter field and also in some other directions, to be followed by co-operation and help most abundantly and willingly provided by a number of other supporters, of whom the great tea industry firms were among the first. Within five years of its start one firm was already in 1938 making not less than 150,000 tons of compost annually.

The campaign now began to take on the aspect of a call for a revolution in farming. The prevailing treatment both of soils and of animals came under discussion and was questioned. Every new idea was forthwith tried out on the land by some pioneer, and the invariable success attending these experiments proved a principal factor in uniting in spirit a number of forward-looking individuals, who practice what they preach under the title of organic farming; of this school 'there are many distinguished exponents.

The campaign evoked from the outset the opposition of most of the official Experiment Stations and Agricultural Colleges, who, with a few honourable exceptions, did not hesitate to pour on it ridicule and contempt; in view of the fact that one of the principal contentions of the farmers of the new school was complete disbelief in artificial manures or in poison sprays the opposition of these interests also could scarcely be in doubt. In spite of this, and in spite of the absence of any official support, funds, or authority, the spread of the new doctrines was amazing. The Indore Process itself is now known and practiced in the following countries and probably in others not named: England, Scotland, and Northern Ireland; Eire; Canada, Australia, New Zealand, South Africa; Rhodesia, Nyasaland, Kenya, Tanganyika, Uganda, West Africa; the West Indies; India; Ceylon; Malaya; Palestine; Italy; the United States of America; Mexico, Costa Rica, Guatemala, Chile, Peru, Salvador, Argentine; and was used by some of our armed forces.

Perhaps the Process has been most slowly adopted in Great Britian, where the experience of two wars has made the population nervous and inclined to be too anxious to follow official authority. The popularity of composting has, however, greatly spread in the last few years among allotment holders and small gardeners, who have gladly welcomed the opportunity of growing their own quality food. Among these the New Zealand box, which is extremely cheap and easy to make and which seems ideally adapted to the needs of such small cultivators, has had a great success. But a number of owners of large estates have also been most anxious to apply the principles of the Process. Their combined efforts together with the co-operation of one or two leading firms making agricultural machinery bid fair to solve the question of suitable machines for the assembling, turning, and spreading of the material, but even without machinery and with our highly paid workers composting can be made to pay handsomely, as has been proved by actual example. An ingenious use of gravity has also been tried to allow the muck needed in composting to drop from one level to another and to permit of the finished material being collected in carts; where large-scale work is to be done this might be a great advantage and only calls for thought in the lay-out. Composting has also come to stay in glass-house work, where it has had the inestimable advantage of eliminating disease. In general, the original Process has been modified in the direction of simplicity. A little experience is needed; many small cultivators begin by making their heaps much too small and much too tight. Full directions for making compost and for constructing the New Zealand box are printed at the end of the present Appendix.

The Process has proved itself completely adaptable to every type of cultivation and every climate, which shows that the principles on which it is based must be sound. At an early stage it was shown to be capable of dealing with the most refractory material. Major Layzell, manager of the Taveta estate of Colonel Grogan, was able in 1935 to compost the unpleasant wastes from sisal, which are of such a nature as to be a veritable nuisance to the countryside; the dumps of solid matter putrefy and smell for miles; the so-called "soup" or fluid waste contaminates the streams and kills the fish; both these evils disappear with composting. Similarly Mr. Dymond, chief chemist to the South African Sugar Company in Natal, succeeded in 1938 in composting the leaves of sugar cane, which are most difficult to break down and may be described as armour-plated. There are other directions in which composting may help to deal with well-known difficulties; thus the composting of water-hyacinth in Bengal, as it was successfully carried out by Mr. Fairlie Watson, superintendent of the governor's estates, Bengal, shows what use could be made of something which up till now has been listed as a noxious weed, a deadly menace to the waterways of India; the composting of water-weeds is a subject to which little thought has been given, but it opens up very great possibilities in view of the fact that such weeds are the perfect agents for catching and saving for us the rich dissolved food materials either in natural streams or in sewage effluent.

In one respect the Indore Process differs from Chinese methods -- it invariably, if properly made, induces a very high temperature in the mass composted, which suffices to kill most weed seeds and all pathogenic germs; the margin of safety is ample. This, of course, is a very important consideration. It has an obvious bearing on the composting of urban wastes, the return of which to the land becomes an even more urgent problem. Their loss, which began about a century ago, cannot but greatly impoverish our soils. The problem becomes even more acute when we realize what an immense shrinkage there has been since 1910 in the supply of animal manure as a result of the substitution of motor for horse-drawn transport.

There are two forms of urban waste, dustbin refuse and nightsoil or sewage. In most countries a beginning could at once be made by the return to the land of the former. In our own country there exist very rich accumulations from the past in the shape of controlled tips. These have been built of unsorted rubbish and have been sealed with a layer of soil or ashes; the rubbish has not been incinerated and its organic content has therefore not been destroyed. On the contrary, owing to the supply of air which remains with the rubbish -- and because of its irregular nature there is ample of this -- this organic content soon becomes completely oxygenized and broken down; it is therefore waiting as rich fertilizing material, which only has to be roughly screened to be of immediate use. The careful investigations of Messrs. B. B. Jones and F. Owen at Wythenshawe in 1932 (Some Notes on the Scientific Aspects of Controlled Tipping, published by the City of Manchester, 1934), showed this material to be free of pathogenic germs; its restoration to our fields would do much to restore them to a good state. Current refuse, which is estimated at about thirteen million tons a year, could thereafter be made available; a plant constructed by the Borough of Southwark in South London has been particularly successful. In 1939 the all-in cost of separation, pulverization, and application to the land of the material in the controlled tips was estimated at 7s. 6d. per ton (letter of Sir Albert Howard to The Times of Sept. 5, 1939).

Neither should the disposal of human nightsoil in a way to benefit agriculture prove difficult. Composting of this material together with vegetable refuse is possible in long pits on perfectly hygenic methods; the resulting manure is pathogenic-free and most valuable. Not only has this been proved by careful experiment (Jackson and Wad at Indore, Dr. Scharff at Singapore and others), but one country, South Africa, has begun to carry out such work on an extensive scale. After pioneering essays done by Mr. van Vuren at Ficksburg the authorities of the Union Government were so impressed that they initiated a training scheme with Mr. van Vuren in charge. The result has been the adoption of composting schemes for this material by over one hundred municipalities serving two-thirds of the total urban population in the Union and including such important centres as Cape Town, Pretoria, Potchefstroom, Johannesburg, Ficksburg, Bloemfontein, Kimberley, Durban, Stellenbosch and Pietermaritzburg. The end product finds a ready sale and will do much to restore the phosphate-exhausted soils of the Union. The whole of this most interesting, new departure, which might well be copied by other countries, has taken place since 1939. Such a system could be inaugurated at a large number of centres and would confer the most distinct benefits on urban communities as well as on the country-side. Details of Mr. van Vuren's work in Howard: The Soil and Health (Farming and Gardening for Health or Disease), Appendix C, The Utilization of Municipal Wastes in South Africa, by Mr. van Vuren himself; for some previous work see Howard: An Agricultural Testament, Appendix C, pp. 235-42, "The Manufacture of Humus from Wastes of the Town and the Village".

Where water-borne sewage has already been undertaken or where the size of the urban centre makes it imperative, the question arises as to how to deal with such sewage. Treatment is already advanced, it being widely recognized that to run it off crude into rivers or streams is a major mistake, though cities well placed in this respect are still tempted to indulge in this faulty practice as the easiest; when they do, the whole contents are lost forever and there is also the continued danger of poisoning waters, especially when not under the immediate influence of strong tides. Elsewhere the sewage is treated by modern processes of activation, from which the solid matter emerges as sludge, an odourless unobjectionable powder when dried, which forms a useful fertilizer. This should be bagged and made available to the allotment holder in small quantities, to whom it would be quite invaluable in view of the difficulty of obtaining animal manure, but few municipalities will take this trouble and much more public pressure is needed.

When the sludge has been disposed of there remains the effluent. The accepted method of dealing with this is to run it into so-called sewage farms; alternatively it is run out to sea and anything it contains is lost. There is here a great need of experimental work, for it would seem likely that a far better principle would be to stimulate a growth of water plants, which would automatically clear the effluent of all its most valuable mineral contents and incorporate them into their own structure; from time to time such water plant growth could be cut and then composted; in this way practically nothing would be lost to us, and the effluent, being almost pure water, could be run off anywhere. This idea still awaits a proper trial.

There is also an alternative principle. This is not to activate but to use a reduction process. Under anaerobic conditions methane and carbon dioxide are produced and almost none of the combined nitrogen is converted into the gaseous state and so lost to the system. The final result is most advantageous; the constant supply of methane produced can help our fuel problem; the resulting sludge is deprived of much of its colloidal and deleterious matter and, after drying, can be safely added to the soil or to the compost heap.

The general conclusion is that this is a problem on which the public has very well-defined rights and also duties; to return wastes to the soil is a debt which the city owes to the countryside. It is no longer possible to argue that this cannot be done; the experience of South Africa, where in less than ten years the whole business was handled in a new way, shows that inititative and a little courage are all that are needed. Even the wastes of the largest cities are capable of recovery and steps should be taken without further delay to see that this is done.

One word of warning is necessary, and this applies to the whole subject of composting rather than merely to the disposal of sewage. Composting has become so popular that the inevitable has happened -- the hope of gain and the desire for notoriety have both crept in. A number of patents have been taken out or, alternatively, secret preparations are being advocated and sold, all stated to be an aid to the making of the best compost; in some cases there has been a real self-delusion and the advocates are quite sincere in what they do. Nevertheless, it cannot be too clearly stated that in the manifold living chemistry of the compost heap neither the claim to secrecy nor the claim to special preparations can for a moment be sustained; the intricacy of the natural processes is far too great to be tied down in any such way and claims in this direction can only be described as misleading. The cultivator will be well advised to make his own compost without such so-called aids, the principles of compost-making cannot conceivably be either patented or concealed, for they are merely a manifestation of natural law, easily understood by all.

Practical Instructions for Making Compost by the Indore Process

1. Composting in Large Gardens

Materials

The first requirement is "organic wastes", that is, plant residues: weeds, leaves, old straw and hay, bracken, reeds, seaweed, hedge trimmings, etc. Spoiled paper, worn-out clothing, leather and sacking can also be added after previous soaking in water. All green material should be partly withered. Hardy woody material should be cut into short lengths and crushed where possible by, for example, wheel traffic. Anything very resistant can be transferred from heap to heap if the first is not enough to break it down.

The second requirement for the compost heap is animal manure, from horses, cattle, sheep, pigs, rabbits or poultry. Nothing is better than freshly used nightsoil for this purpose which, if the composting be well done and the nightsoll be immediately covered with humus, is safe and entirely without offence. Dried sewage sludge can also be used.

The third requirement is earth, if possible mixed with ground limestone in the form of grit, wood ashes, or preferably a mixture of all three. The earth, etc., is needed as a neutralizing agent to keep down acidity.

The fourth requirement is water. In general, rain will supply this need (in fact it may be said that protection from rain is more important in Great Britian than the provision of water, although there are occasions when it must be added). The heap must not be too wet, the consistency of a squeezed sponge being aimed at. Liquid manure (for instance, bedroom stops or drainage from a pig cote) is of the very highest value.

During the early stages of decomposition air is required in large quantities by the fungi and germs in the heap. This is got by diffusion from the atmosphere, so the heap must be made loose. Later, after the fungous stage is over and the material has crumbled and darkened, the heap has reached a stage where the fermentation goes on without much air. The germs then obtain some of their oxygen from the decomposing material itself.

Making Large Compost Heaps

Composition of the Heap. Make oblong heaps upon earth, NOT concrete. If possible, a bottom should be made in a similar manner to that of a haystack. Hedge trimmings, bush fruit prunings or other materials which will act as an open base are suitable. This assists aeration. On this base the heap is built. It consists of an intimate mixture of 3 or 4 parts by volume of mixed vegetable wastes, 1 part by volume of animal manure, and a good sprinkling of the neutralizing agent made up of equal volumes of earth and fine limestone grit. (Where wood ashes are available, these may replace a portion of the limestone grit.) By mixing the materials as the heap is assembled, the fermentation is assisted and much labour in turning is avoided. Continue the building of the heap till a height of 4 to 5 feet is reached. It will sink later to about 3 feet. A final layer of manure 2 to 3 inches thick followed by a sprinkling of mixed earth and limestone grit, which should completely cover the manure, will complete each section of the heap.

In districts of heavy rainfall it is always advisable to arrange for the finishing layers to form a double slope.

In most parts of our island a temporary covering IS ESSENTIAL to protect the heap against excessive rain. Boughs or poles should be laid across the heap to raise the covering.

Size of the Heap. The minimum size for a heap is 12 ft. x 5 ft. x 4 ft. high. With any size smaller, the ratio of cooling surface to volume is too great. In such cases use the New Zealand box described below.

When making the heap always build it in sections of about 4 feet long and complete each section to the full height before beginning the next. The second section is then built close up to the first and completed before beginning the third and so on till the full length of the heap is reached. In this way no time is lost -- fermentation in each completed section begins at once. In addition, each section protects its neighbour and the heat is conserved. Space must be allowed for turning the heap.

Supply of Air. It is very important that the heap should be made as loose as possible in order to permit of copious aeration, and care should be taken not to step on the heap whilst building.

Aeration can be greatly assisted by making vertical holes in the heap by means of a rod or crowbar. Some people stand a rod upright first and make the section of the heap around it. The ventilation holes should be made 4 inches wide by working the rod to and fro. The holes should be 3 feet apart.

Turning the Heap. Provided due care is taken when assembling the heap to make a thorough mixture of the materials, only one turn will be needed. This should be done when the intense fermentation (which sets in at the beginning and when temperatures round 150° F. are reached) begins to subdue and the heap begins to cool. This will occur about three weeks after assembling, by which time the inside of the heap has turned white due to the development of fungus growth.

At the end of three weeks or so the heap is turned from one end, care being taken to bring the outside to the inside of the remade heap. Provided everything has gone well, no holes need be made in the turned heap. The heap can now be left to mature.

Completion, Position of Heap, and General Management. Three months after the process began the material is ready for application to the land. It consists of a finely divided product of which about 80 per cent will pass through a sieve of six meshes to the inch.

Protection against excessive rain has already been mentioned. The opposite possibility of dryness must be watched for and, if rain be insufficient, water must be added. This must not be sluiced on to the heap with a bucket but sprayed either by a hose with a nozzle or from a can with a rose. It has already been mentioned that the material should have sufficient moisture to give it the consistency of a squeezed sponge. That is the guide to which the maker should work. It is impossible to lay down a hard and fast rule concerning either the protection of the heap from rain or the addition of water in the absence of rain. The heap has life and must be looked after like all living things.

Once the technique of compost making has been mastered and a satisfactory product has been obtained, it is possible to save a certain amount of watering by using fresh green material in the heap. But care must be taken not to overdo this, otherwise silage and not compost will result.

If a sheltered site can be chosen facing south and with a wind-break from the north, so much the better. This applies particularly where the heaps are small and for these smaller heaps, where possible, protection should be given on three sides by means of walls or hedges; but the heap must never be banked up against a wall. The system by which mutual protection is given by old and new heaps should also be used wherever possible.

2. Composting in Small Gardens

In small gardens where the quantity of wastes is considerable two minor difficulties are often encountered. Wind and rain interfere with the rate of fermentation. Wind lowers the temperature of the outer layers of the heap and also removes large quantities of moisture. Excessive rain, by making the whole mass sodden, interferes with the air supply. Low temperatures, dryness, and shortage of oxygen are all harmful factors, because they impede the work of the fungi and bacteria engaged in the synthesis of humus which work best at temperatures ranging from 150 to 90 deg. F., when the heap is moist and when there is ample oxygen.

These difficulties can be overcome by the use of a pair of New Zealand boxes. This box was devised by the New Zealand Humic Compost Club for use in the gardens of New Zealand and works well in this country. A suitable box can be made as follows:

Materials Required for Each Box. Six 3 ft. 3 in. lengths of 2 in. x 2 in. for uprights. Twenty-four 4 ft. lengths of 6 in. x 1 in. board for the four sides of the box. The unplaned timber should be oiled with old motor oil to preserve it, but tar or cresote should not be used.

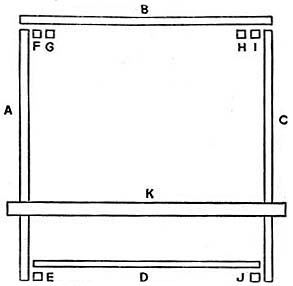

The box (see diagram), which has no bottom, stands on the ground, so that it can be moved to a new site alongside. First nail the side A to the uprights E and F. Next nail back B to the uprights G and H. Next nail the side C to the uprights I and J. When nailing the boards on to the uprights, leave a half-inch gap to provide ventilation. The three sides of the box are now complete. The sides and end are bolted together by means of four bolts -- each fitted with two washers and a nut which unscrews on the outside -- which join the back B to the uprights F and L. The front D is made up of loose boards, 6 in. x I in., slipped behind the uprights E and J as the heap rises. To prevent the sides A and C from spreading outwards use a wooden bar, 2 in. x 1-1/2 in., with two wooden blocks, 3 in. x 2 in. x 1-1/2 in., as indicated in the ground plan below of the box and the elevation of the bar K.

When the box has to be removed to a new site, remove the loose boards and the four bolts, and re-erect the box in a fresh place.

The New Zealand Compost Box

Plan of box showing bar in position.

|

A, B, and C are the sides, each consisting of six boards each 4 ft. x 6 in. x 1 in., nailed to the uprights half an inch apart to allow ventilation.

D is the loose front (six boards).

E, F, G, H, I, and J are the uprights (each 3 ft. 3 in. long).

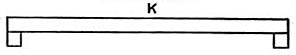

K is the bar, provided with a block at each end, to sit on top of the sides A and C to stop them spreading.

The bar in section.

|

Making the Heap. Having made the two boxes, throw your mixed vegetable material (broken or cut if necessary into lengths a few inches long) into one of them as it comes to hand, together with one-third the volume of manure and a little earth and limestone grit, mixing the wastes, manure, soil and grit as the box is filled. The proportion by volume of mixed vegetable wastes to manure should be 3 or 4 to 1. All garden or unused kitchen waste may be used, including weeds, lawn mowings, crop residues, leaves, hedge clippings, and seaweed when available. Where animal manure or soiled animal bedding are not available, substitutes such as dried sewage sludge, dried blood, hoof and horn meal, or fish manure may be used, but in these cases only a very thin -film about a quarter to an eighth of an inch thick is needed for every six inches of vegetable waste. If none of these substitutes can be obtained, the heap can be kept moist -- not wet and sodden -- by means of bedroom slops. Animal wastes in some form are essential.

Next water this mixed material with a hose fitted with a rose, or with a watering-can, until it is wet but not sodden. Continue this building and watering process until the box will take no more material. Rain (which is a saturated solution of oxygen) should be used wherever possible instead of the rose to keep the contents of the box moist.

After the box is half full, make and maintain one vertical ventilation hole in the middle by thrusting a light crowbar or stout garden stake into the heap and working it from side to side. The hole should go as far as the earth underneath the box. The box should be protected from rain and sun by means of two pieces of old corrugated sheeting, each 58 in. x 26 in. These are kept in position by means of bricks or stones.

Two things must be watched: (1) an unpleasant smell or flies attempting to breed in the box. This ought not to happen and is generally caused by over-watering or want of attention to the details of filling the box. If it occurs, the box should be emptied at once and then refilled. (2) Fermentation may slow down for want of moisture, when the mass should be watered. Experience will teach how much water should be added when filling the box.

Turning the Compost. Provided due care is taken in filling the box, no turning is necessary. After four weeks or so the contents should be moved into the empty box, watered if needed to keep damp, and then allowed to ripen for a month or six weeks. No ventilation vents are needed in the second box. The compost, which weighs about three-quarters of a ton, is then ready for use and should be applied to the garden as soon as possible. If it must be stored, it should be dried in the sun and kept in an open shed.

3. Composting on the Farm

The principles set out above for compost making in the garden apply equally to the farm. The only difference is that on the farm the heaps are very much larger and much of the work can be done by a tractor-driven muck-shifting machine, of which several types are on the market. Every farmer, however, and those members of his labour force engaged in compost making would do well to begin operations in their gardens and to master thoroughly the above-described technique essential for the making of really high-quality compost. They can then apply their first-hand experience to the assembly and management of the large mechanized heap, always remembering that the heap is alive, that the work of compost making is being done for them by living organisms-moulds and microbeswhich require just as much care, thought, and management as their livestock. In this task all concerned will do well to forget everything they have ever learned about chemistry and to bear in mind that the principles underlying composting are biological and not chemical.

Mixing the Raw Materials. As will be evident from the above, one of the great labour-saving devices in compost making is to mix the materials -- vegetable and animal wastes with a little soil and limestone grit -- under the livestock in the cowsheds, loose boxes, piggeries, and so forth. This reduces much of the expense involved in turning the heaps. Further, the treading of the animals helps to fracture the outer covering of straw which was designed by Nature to protect the crops from the inroads of pests -- mostly fungi and insects; for the compost heap none of the litter needs any protection from fungi -- the sooner this protection is destroyed, the quicker the fungi can convert the material into humus. The bedding of the livestock should be as ample as possible, so that all the litter can be well broken up by treading and thoroughly impregnated with urine and mixed with dung. As the urine of the animals is one of the chief foods of the compost-making organisms, it must not be allowed to run to waste but must be completely absorbed on the floor as it falls from the animals by such materials as shavings, peat, and sawdust, as well as straw.

To keep down the acidity in the compost heap a mixture of equal parts of limestone grit and soil should be scattered on the new bedding after this is laid down. This does two things: (1) the compost heap is kept sweet; (2) a small continuous dressing of limestone constantly reaches the land and helps to lower its acidity.

The soiled bedding is now ready for the compost heap, to which it should be transferred as quickly and as cheaply as possible. The exact methods used will depend on circumstances such as the -lay-out of the buildings and the position and size of the composting area. One difficulty, which can only be removed by time and experience, arises from the fact that when the present farm buildings were designed, labour was cheap and abundant and the importance of compost making was not understood. But as time goes on, simple and cheap modifications of the existing lay-out to assist in humus manufacture are certain to be made.

The compost heaps should be assembled in complete sections, each about 4 ft. wide and 4 to 5 ft. high, and ventilation holes should be made about 3 ft. apart. The second section should be made close to the first and completed with ventilation holes before beginning the third and so on till the heap is finished.

The heap can be turned by the machine once or twice as may be necessary. The finished compost can be loaded into carts or manure distributors by the same implement.

On sloping land it is sometimes possible to save an enormous amount of work by the utilization of the force of gravity. When the cowsheds are built on the levelled top of a small hill, a composting terrace can be excavated at a lower level so that the soiled bedding is never lifted but allowed to fall from the floor of the cowshed to the composting terrace below. Here the compost heaps are made and turned by hand labour. A third terrace below the second is metalled like a road for the carts or manure distributors which can be filled without lifting the finished compost. This labour-saving system has been adopted with great success by a retired officer of the army in Tanganyika. There the raw material for composting makes two descents on the way to the field -- the first from the cowsheds to the composting terrace, the second from this terrace into the carts. As much of Great Britian is hilly, it may be possible here and there to adapt this simple gravitational method of composting to local conditions and to save an enormous amount of heavy work.

Another labour-saving method is to keep the animals in two open yards, each about 100 yards long and 20 wide (enclosed by a suitable wire fence), on either side of a sunken road so that the finished compost can be forked into the carts without any lifting. These long yards are used alternatively so that the manufacture of compost is continuous.

The Importance of Quality in Compost Making. Too much emphasis cannot be laid on the importance of quality in farm compost. The higher the quality, the better the crops and the finer the livestock.

Next: B. List of Books

Back to Contents

Back to Small Farms Library index

Community development | Rural development

City farms | Organic gardening | Composting | Small farms | Biofuel | Solar box cookers

Trees, soil and water | Seeds of the world | Appropriate technology | Project vehicles

Home | What people are saying about us | About Handmade Projects

Projects | Internet | Schools projects | Sitemap | Site Search | Donations | Contact us

|