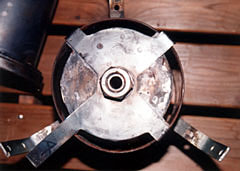

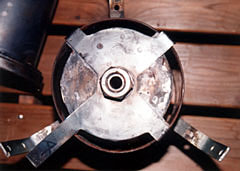

Picture 1 -- Prototype #4

|

We've been working on developing a small inverted downdraft gasifier woodstove for a schools project, initially in Japan, but good for anywhere. We've made four prototypes so far: they work, but they're not perfect, not good enough for a schools project. We could use some help!

See Wood fires that fit

Wood-gas stoves

Background

Japan makes itself unpopular worldwide by throwing away 130 million pairs of disposable wooden chopsticks per DAY!!! -- made out of other people's forests, not their own. Some countries are being seriously deforested because of Japan's throw-away chopsticks. The Japanese are not unaware of the problem, but not a lot gets done, beyond tokenism (such as a disposable chopsticks wrapper from one of the ubiquitous convenience stores, bafflingly labelled "Ecology Earth Effort").

Some of the schools are aware of the problem -- some don't use disposable chopsticks, some even collect them and do things with them -- one enterprising school turns them into paper and makes postcards out of them.

We propose burning them in an improved cookstove. Preferably it should be a stove that a school class could make in a few hours, preferably out of "tincanium" (millions of waste tin cans in Japan, they get recycled but it's a good part of the lesson) -- but this isn't essential, it's more important to have a design that works well. If too difficult for a class to make, it could perhaps be supplied in kit form. Mainly it has to work without fail, and without gassing everybody while cooking the rice for a school lunch.

Picture 2 -- secondary air is pre-heated by the fire, around the sides and through the centre pipe.

|

It's not that long ago that everyone still cooked with charcoal, so to get TWO cookings out of a handful of chopsticks, one with the chopsticks, the other with the charcoal, has a lot of lesson potential. The lesson about how such stoves can improve lives in the Third World, and the conditions there, along with the obvious lesson of the disposable chopsticks themselves, should make it a worthwhile schools project.

Work so far

We used Tom Reed's basic two-coffee-cans design as a starting point, but scaled down. See A Wood-gas Stove For Developing Countries, T. B. Reed and Ronal Larson (268k Acrobat file)

We're still not sure whether such stove designs can be scaled down effectively this way, but this first design was beginner's luck -- very rough-and-ready, just to see if we could do it, but it worked surprisingly well.

It was made out of two 400g tomato cans, one with lots of holes punched in the bottom and a primitive slider to control the air supply, the second can with bottom removed and fitted on top of the first can, with a small gap. It burned for half an hour, and left us with a nice pile of charcoal sticks.

Picture 3 -- The lever next to the leg on the left controls the primary air-supply. The rim of the inner can is 0.8cm below the outer can rim; the top of the centre-pipe is flush with the inner-can rim.

|

The second attempt didn't work as well, nor did the third. The stoves were difficult to light, they kept going out, when they did condescend to burn they smoked a lot and stank, and obviously had air-supply problems.

I shut off the primary air-supply at the bottom of the third stove, connecting a shallow can under the stove, airtight, and led in an air-supply from a fishtank aerator pump -- not a great deal of air, but it made all the difference: the stove worked much better with the pump than without it.

But we didn't want to use a pump or a powered fan -- a stand-alone stove without any externals would be far better, if we could only get it to work properly.

I was thinking of insulating the stove with a papercrete mixture, but then decided instead to try harnessing the waste heat to warm the secondary air-supply, which seemed to be the main problem. This involved putting the bottom can inside a somewhat bigger can, with the secondary air-supply coming up from the bottom, to be warmed by the heat of the fire in the inner can. I also put a half-inch copper pipe up through the centre of the can, also supplied with air from underneath, as an additional secondary air-supply, also heated by the fire. This seemed more hopeful. The top can fitted into the lid of the outer can below, containing the secondary air supply from below.

Pictures 8-9 -- Secondary air via the centre-pipe and round the sides is independent of primary air-supply.

|

This stove works much better. It certainly burns well -- rather too well: flames roar up much higher than the rim of the top can. It takes 50 pairs of chopsticks, cut in half, weight 200 grams, standing vertically. It burns for 25 minutes to half an hour, and will boil half a litre of water from 15 deg C in four minutes. It leaves 20-25 grams of charcoal.

But it smokes a bit, sporadically, obviously tars and CO are being released -- not healthy. The flame is yellow-orange, tinged with blue. The jet from the centre pipe seems to work best, with more of a blue flame mingling with the yellow-orange from the heated air coming in from round the side. It seems to work rather better as the fire progresses down the can towards the bottom. Near the bottom it works really well.

One parameter is the size of chopsticks -- 18-21 cm long. A stove that took full-sized chopsticks might be rather big, though that could be the way to go. So far we've worked with half-size: the burner can has about 1cm under the grille and allows for 9-10.5cm wood standing upright with 1cm clear below the rim -- overall height 12.5cm, diameter 9cm.

I tried using a wick, inserting a smaller can into the top can, but didn't get anywhere with it, it didn't work at all.

Any advice would be very welcome indeed! Please send suggestions/comments to:

keith@journeytoforever.org

Keith Addison

Journey to Forever

Handmade Projects

Tokyo

|

|

|

|

|

|

|

|

|

|

|

Picture 4 -- Secondary air via the centre-pipe and round the sides, primary air is controlled by the slider.

|

|

Picture 5 -- Primary air-supply set wide open.

|

|

|

|

|

|

|

|

Picture 6 -- Primary air-supply half-open.

|

|

Picture 7 -- Primary air-supply closed.

|

|

Global wood

David Morris of the Institute for Local Self-Reliance wrote: "A few years ago I was eating at a St. Paul restaurant. After lunch I picked up a toothpick wrapped in plastic. On the plastic was printed the word, 'Japan.' Now Japan has little wood and no oil. Nevertheless it has become efficient enough in our global economy to bring little pieces of wood and barrels of oil to Japan, wrap the one in the other and send them to Minnesota. This toothpick may have traveled 50,000 miles. But never fear, we are retaliating in kind. A Hibbing, Minnesota factory now produces a billion disposable chopsticks a year for sale in Japan. In my mind's eye I see two ships passing one another in the northern Pacific. One carries little pieces of Minnesota wood bound for Japan; the other carries little pieces of Japanese wood bound for Minnesota. Such is the logic of free trade."

In Tokyo we came across a discarded NASA emergency survival kit, unopened. It contained some crackers and sweets, a small chemical stove, a can-opener (you've no idea how thrilled we are to have a genuine NASA can-opener), and an old-fashioned wooden box of waterproof matches, so labelled in three languages, with the legend: "Made in Australia, distributed by Coghlan's Ltd, Winnipeg, Canada". (See Exhibit A, right.) Did they take the wood from the Canadian forests to relatively forest-free Australia so they could make the matches there, and then ship them back to Canada for packaging, and then to Tokyo, via NASA? At a profit, yet? What did they use, a Space Shuttle?

In Tokyo we came across a discarded NASA emergency survival kit, unopened. It contained some crackers and sweets, a small chemical stove, a can-opener (you've no idea how thrilled we are to have a genuine NASA can-opener), and an old-fashioned wooden box of waterproof matches, so labelled in three languages, with the legend: "Made in Australia, distributed by Coghlan's Ltd, Winnipeg, Canada". (See Exhibit A, right.) Did they take the wood from the Canadian forests to relatively forest-free Australia so they could make the matches there, and then ship them back to Canada for packaging, and then to Tokyo, via NASA? At a profit, yet? What did they use, a Space Shuttle?

In Tokyo we came across a discarded NASA emergency survival kit, unopened. It contained some crackers and sweets, a small chemical stove, a can-opener (you've no idea how thrilled we are to have a genuine NASA can-opener), and an old-fashioned wooden box of waterproof matches, so labelled in three languages, with the legend: "Made in Australia, distributed by Coghlan's Ltd, Winnipeg, Canada". (See Exhibit A, right.) Did they take the wood from the Canadian forests to relatively forest-free Australia so they could make the matches there, and then ship them back to Canada for packaging, and then to Tokyo, via NASA? At a profit, yet? What did they use, a Space Shuttle?

In Tokyo we came across a discarded NASA emergency survival kit, unopened. It contained some crackers and sweets, a small chemical stove, a can-opener (you've no idea how thrilled we are to have a genuine NASA can-opener), and an old-fashioned wooden box of waterproof matches, so labelled in three languages, with the legend: "Made in Australia, distributed by Coghlan's Ltd, Winnipeg, Canada". (See Exhibit A, right.) Did they take the wood from the Canadian forests to relatively forest-free Australia so they could make the matches there, and then ship them back to Canada for packaging, and then to Tokyo, via NASA? At a profit, yet? What did they use, a Space Shuttle?